Bugatti's factory of dreams – Molsheim

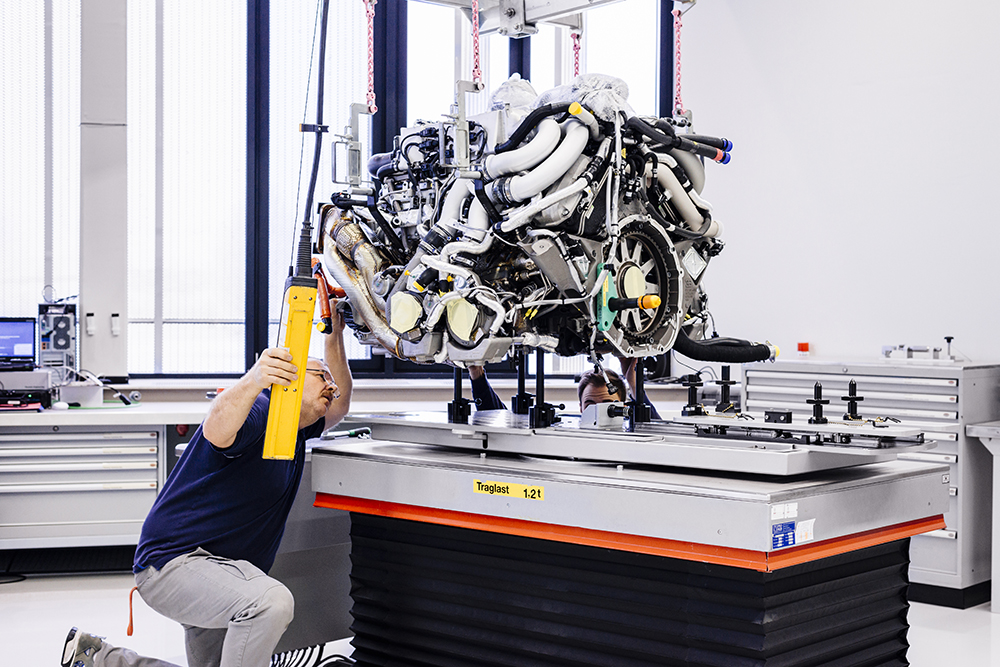

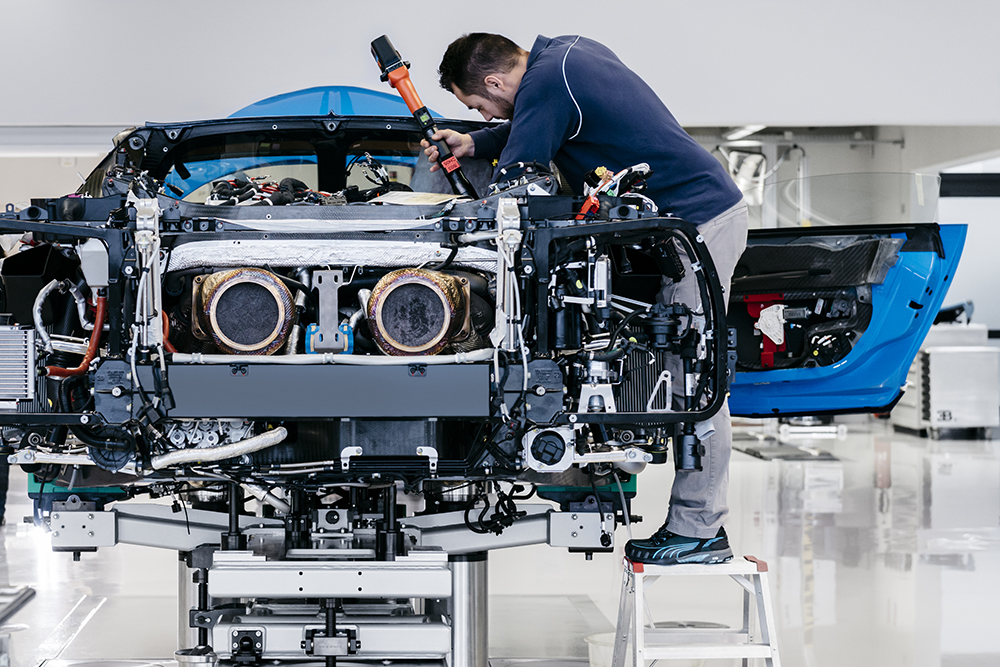

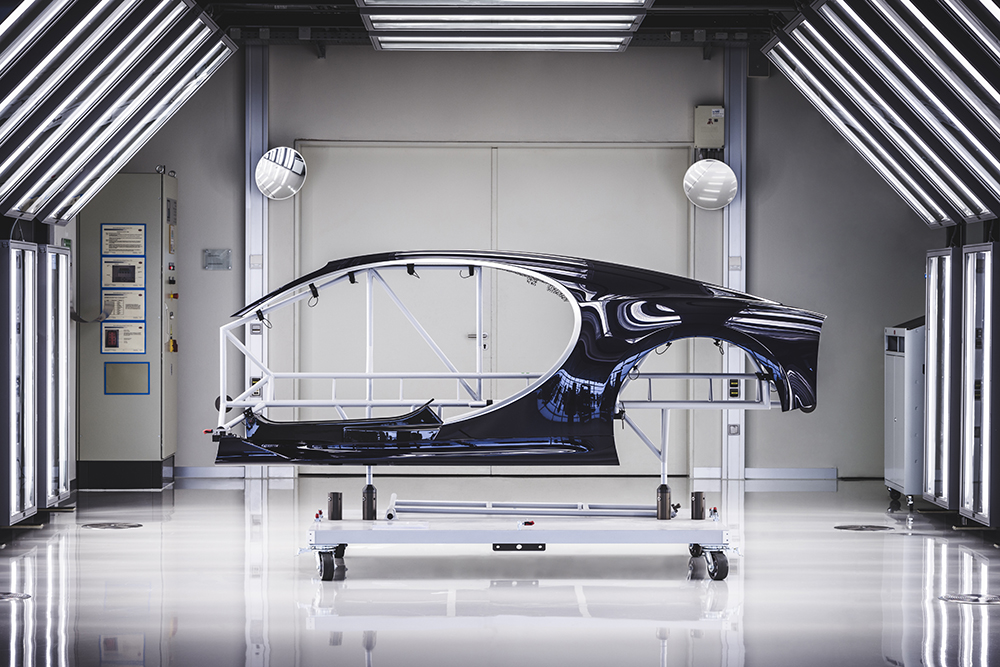

Series production of the Bugatti Chiron is rapidly gathering pace. Currently, 12 super sports cars are taking shape in the French luxury brand’s production facility, the so called 'Atelier' at the company’s headquarters. It is planned to deliver the first vehicles to customers in the first quarter of 2017 and to build up to 70 of these cars this year. On average, about six months pass between the start of production and the delivery of a Chiron. 20 employees in the Atelier assemble the world’s most powerful, fastest, most luxurious and most exclusive production super sports car from more than 1,800 individual parts, working solely by hand. The Chiron is subjected to the most stringent acceptance tests and quality controls before it is delivered to the customer. Many modifications to the facility at Molsheim were made for the assembly of the 1,500 bhp super sports car to take account of its higher performance and the generally more complex nature of the new product and its production process.

Molsheim in an idyllic location in Alsace, has been the home of the marque since it was founded in 1909. These images capture the build process of the new Chiron and the hi-tech facility in which it is pieced together. Images © 2017 Benjamin Antony Monn for Bugatti Automobiles S.A.S.