Bugatti’s Divo ‘Lady Bug’

If you’re a Bugatti customer, then chances are your pockets are a little deeper than most. So, when it came to spec'ing their new hypercar, one customer took what was possible to another level.

With the recently completed Divo ‘Lady Bug’, the French luxury brand has demonstrated its high level of expertise in bespoke application and hand craftsmanship. In a timeframe of around two years, a very special Divo was created in close collaboration with one Bugatti customer, tailored with a one-of-a-kind custom paint scheme among other truly unique features.

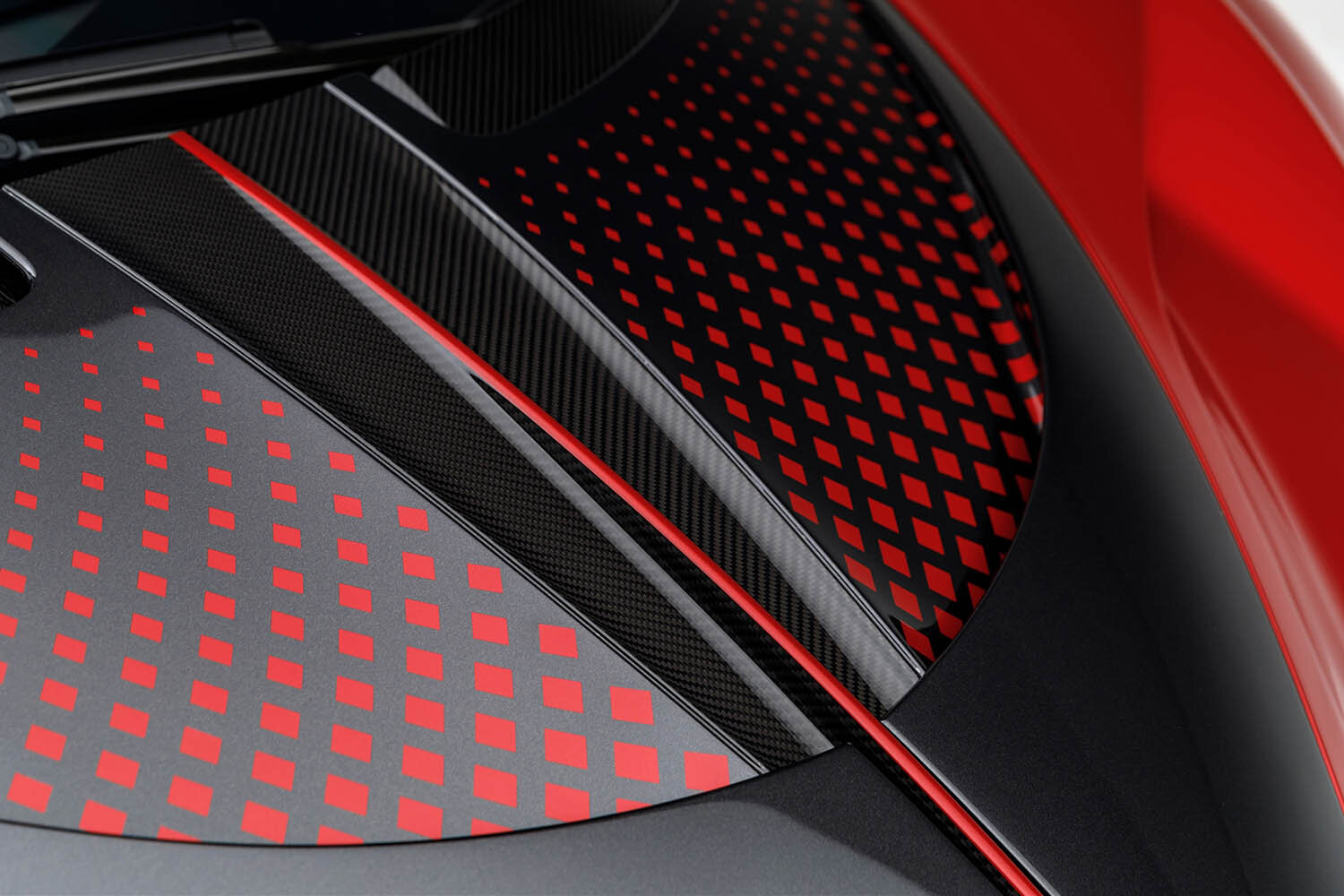

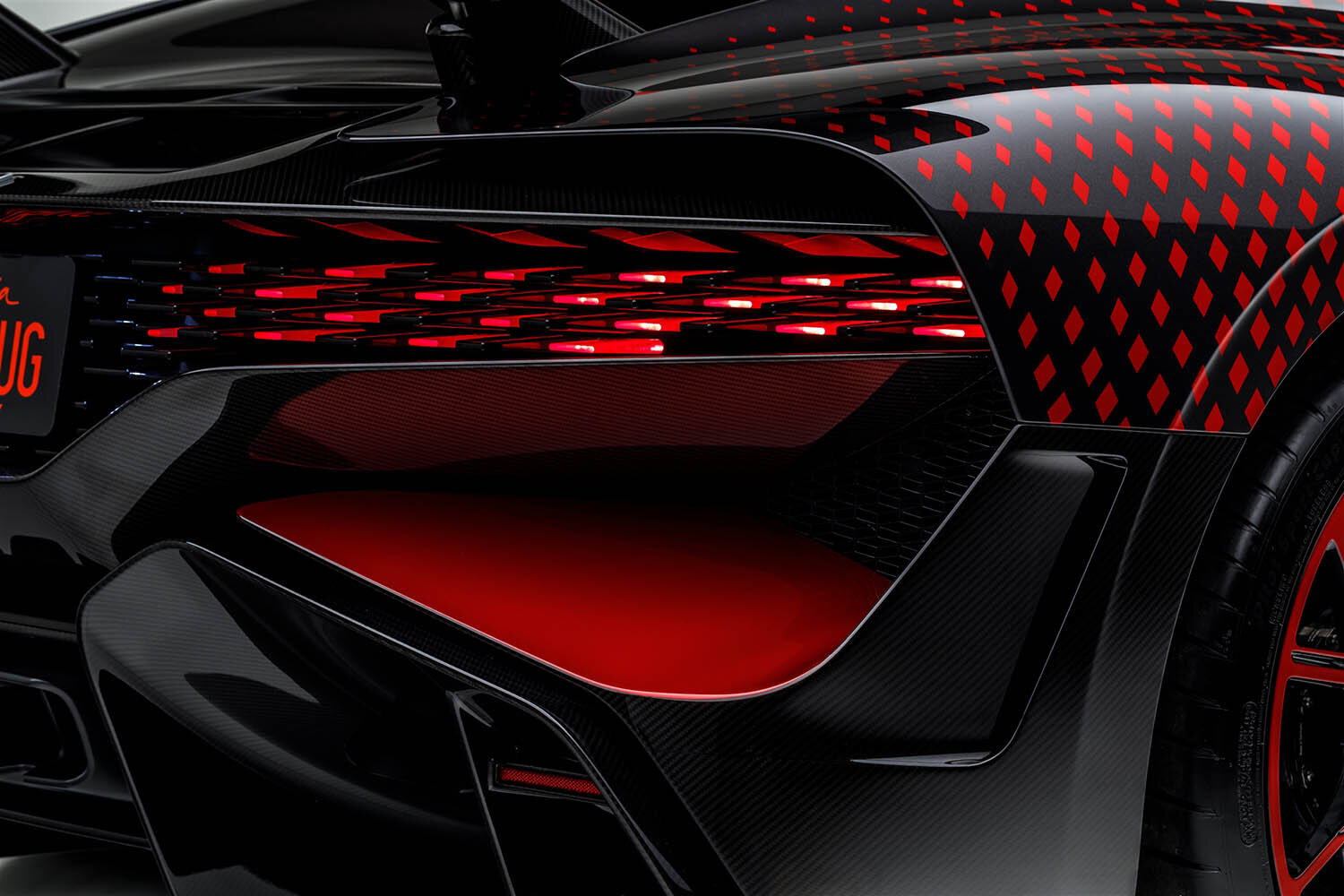

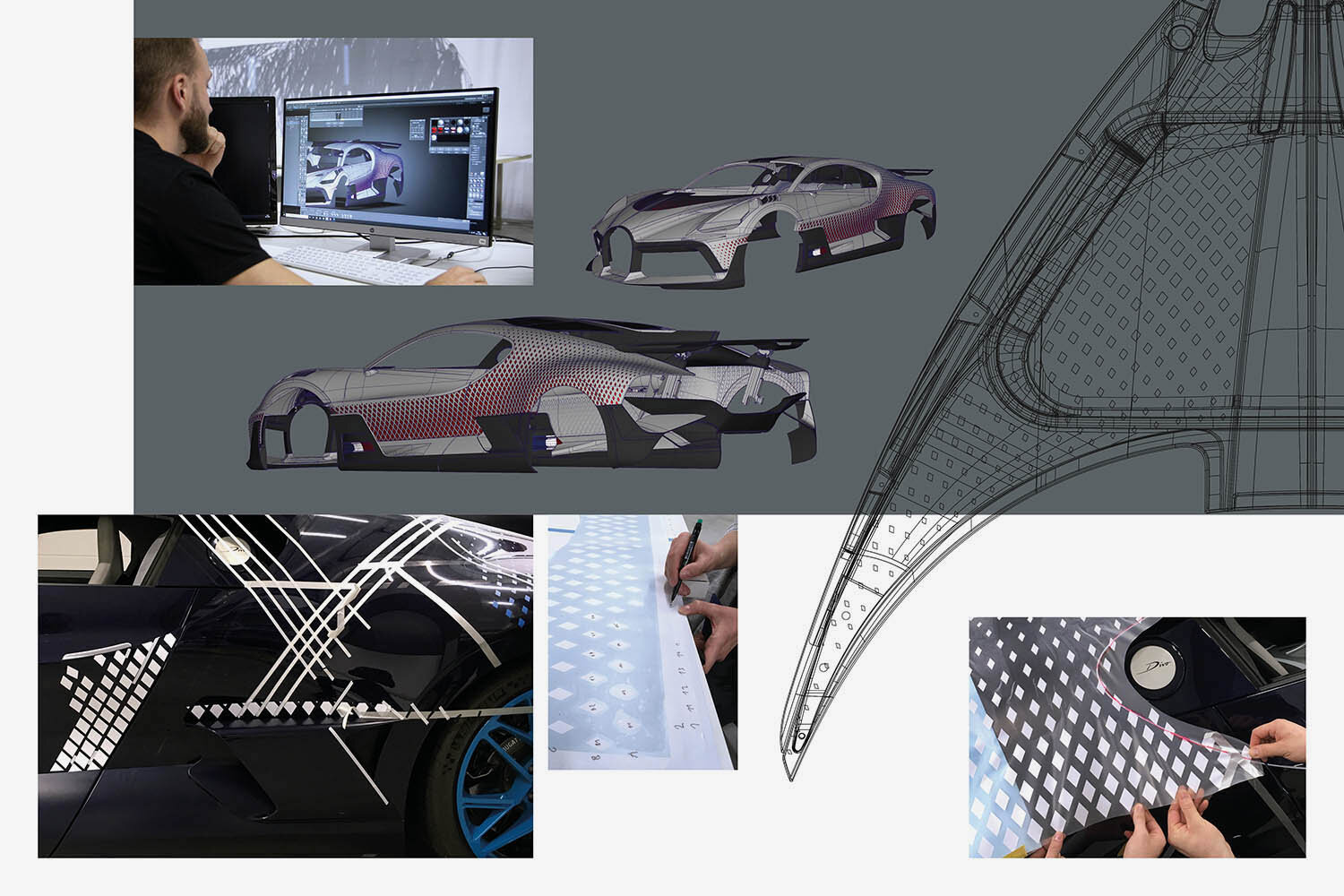

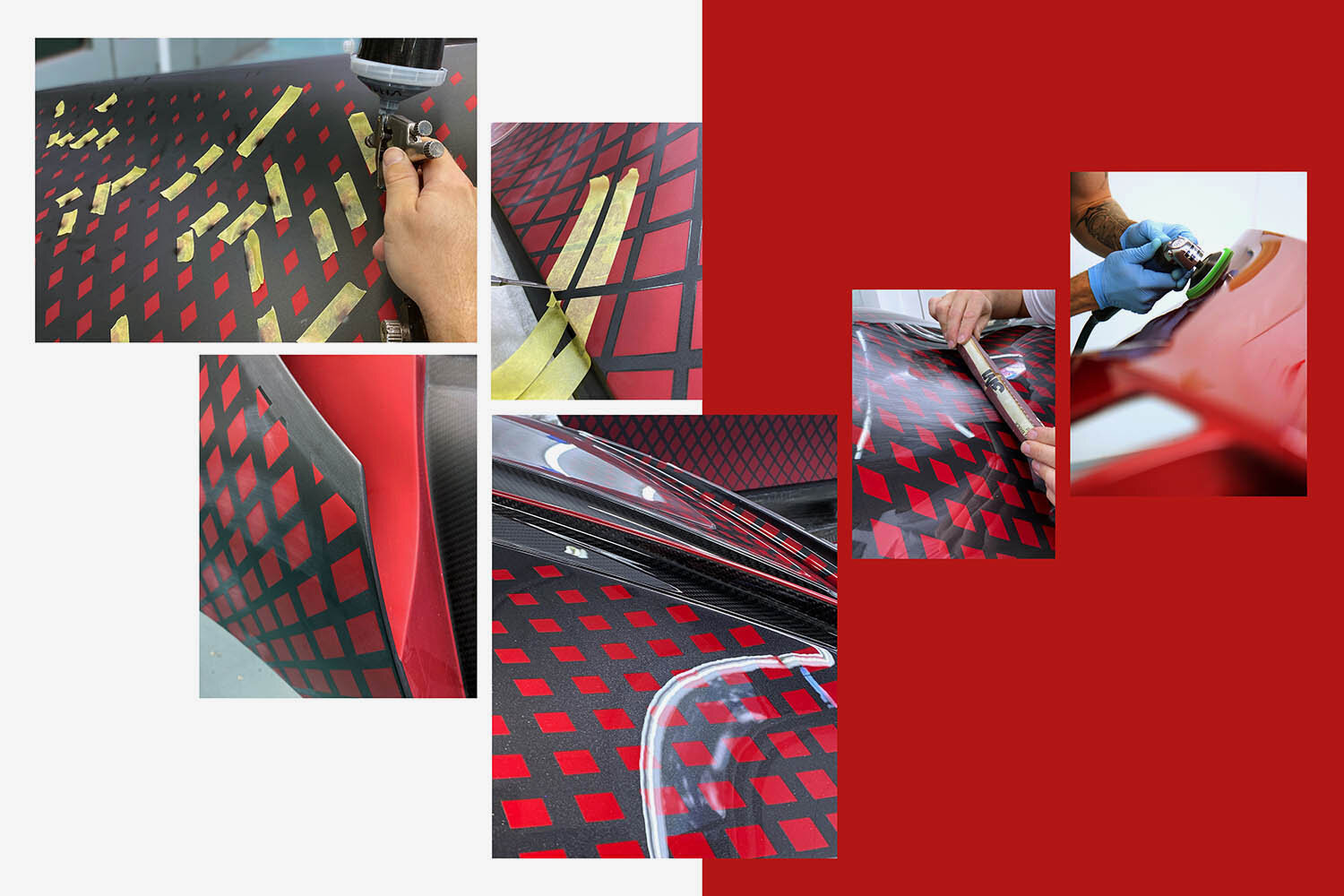

Shortly after the world premiere of the Divo in August 2018, the idea for a geometric-dynamic algorithmic fading pattern on the bodywork emerged in collaboration with the customer. What the collector from the US had in mind was a strict geometric pattern consisting of diamond shapes in a unique colour contrast. In collaboration with the collector, the Bugatti design and development team then set about developing the special colours ‘Customer Special Red’ and ‘Graphite’ – both metallic tones – to achieve the contrasting effect. The diamond pattern was designed to run precisely from the front over the sides to the rear – matching the silhouette of the Divo.

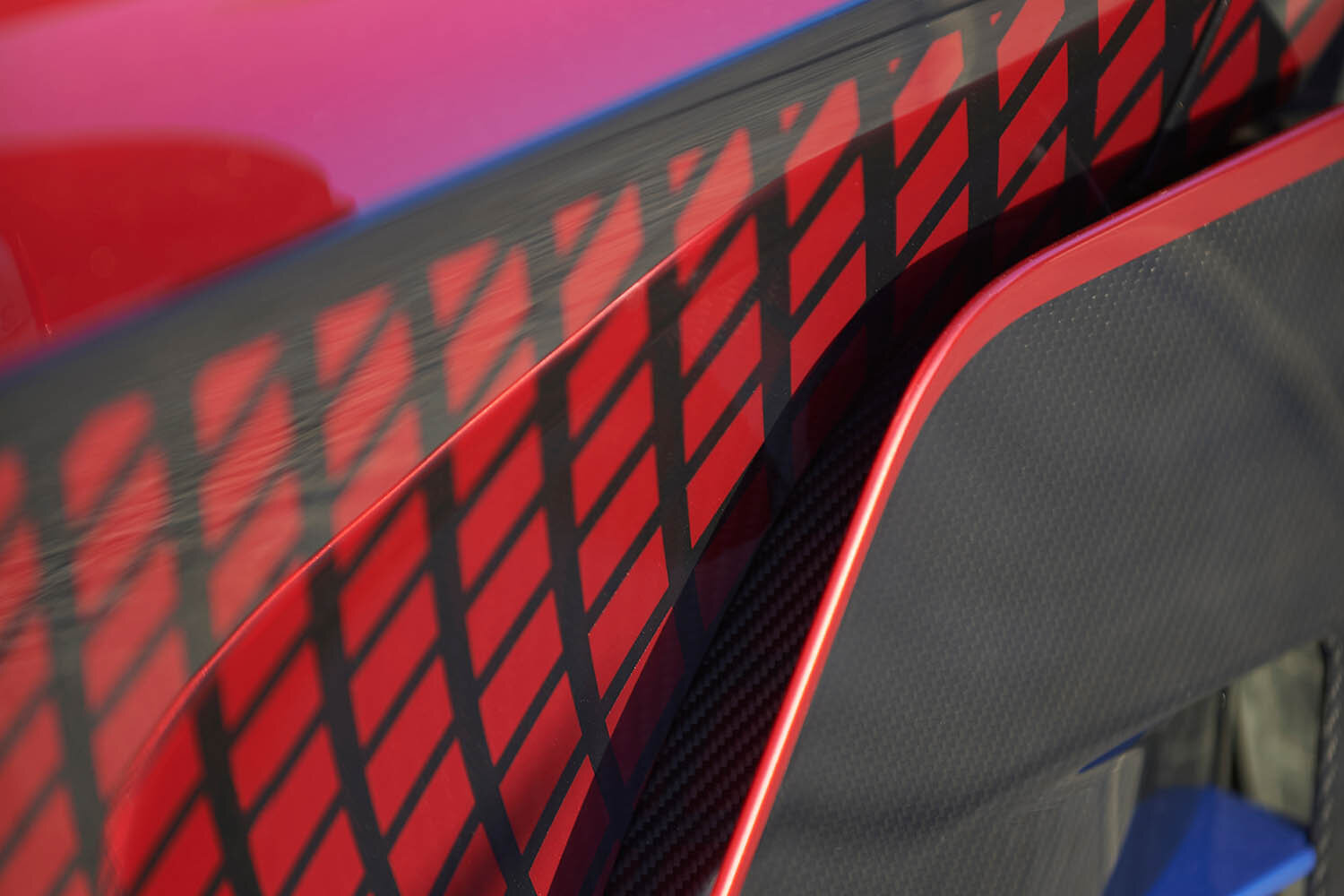

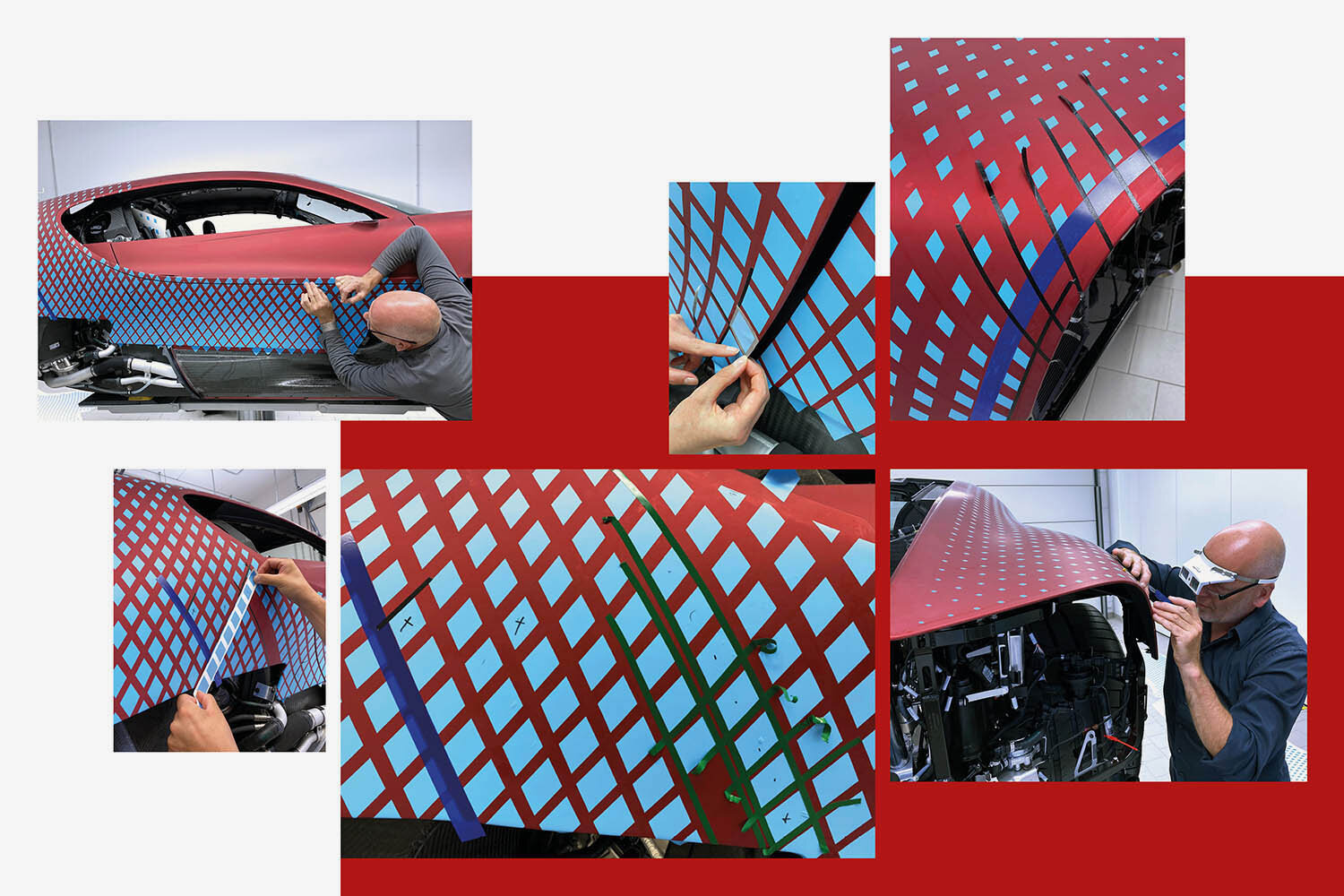

It took the team over a year-and-a-half to find and implement the technical and graphic solutions. However, few could have predicted how complex and difficult it would be to paint the diamonds onto the car body with precision and exact definition. This was due to the fact that the digital patterns in the CAD program bear little resemblance to reality: owing to the three-dimensional, sculptural form of the Divo with its contours, curves an ribs, the 2D-printed diamonds became distorted on the surface of the exclusive hyper sports car. As a result, they had to be digitally modified. All it took was one millimetre’s difference to ruin the entire visual effect. The diamonds also had to be positioned perfectly on the roofline, doors and rear fender edge in order to achieve a clean visual finish. Together with the customer, CAD modellers developed and simulated a diamond pattern design with around 1,600 diamonds. A highly complex and time-consuming task.

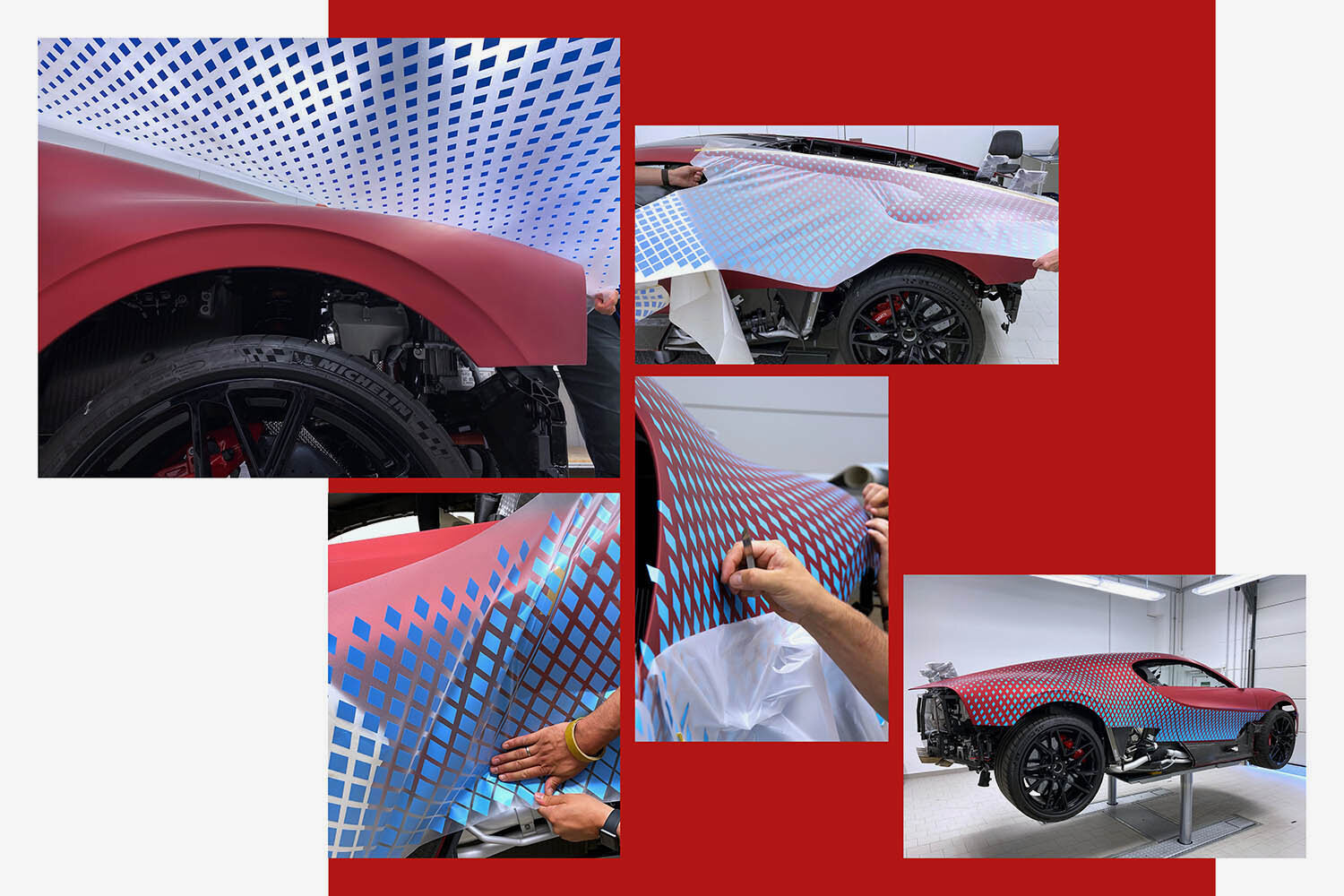

Weeks passed until the designers were satisfied with the result. Six metre long films applied precisely to the body of a test vehicle were used to check the pattern. With considerable patience, craftsmanship and skill, the designers finally found a way to match the CAD data with reality and pull the film over the deeply concave d surface without the diamonds becoming distorted or developing folds.

The diamonds in the film are separated and transferred onto a transfer film, which is then stuck onto the body. Each one of the approximately 1,600 diamonds is checked and realigned if necessary. In early 2020, countless hours were spent on a test vehicle until the developers and designers were satisfied with the procedure. Shortly before the car was delivered to the customer, the final rehearsal took place on another test vehicle. With considerable patience and instinct, the team first of all applied the film to the roofline with millimetre precision, constantly checking the positioning in relation to the door joint line and rear end.

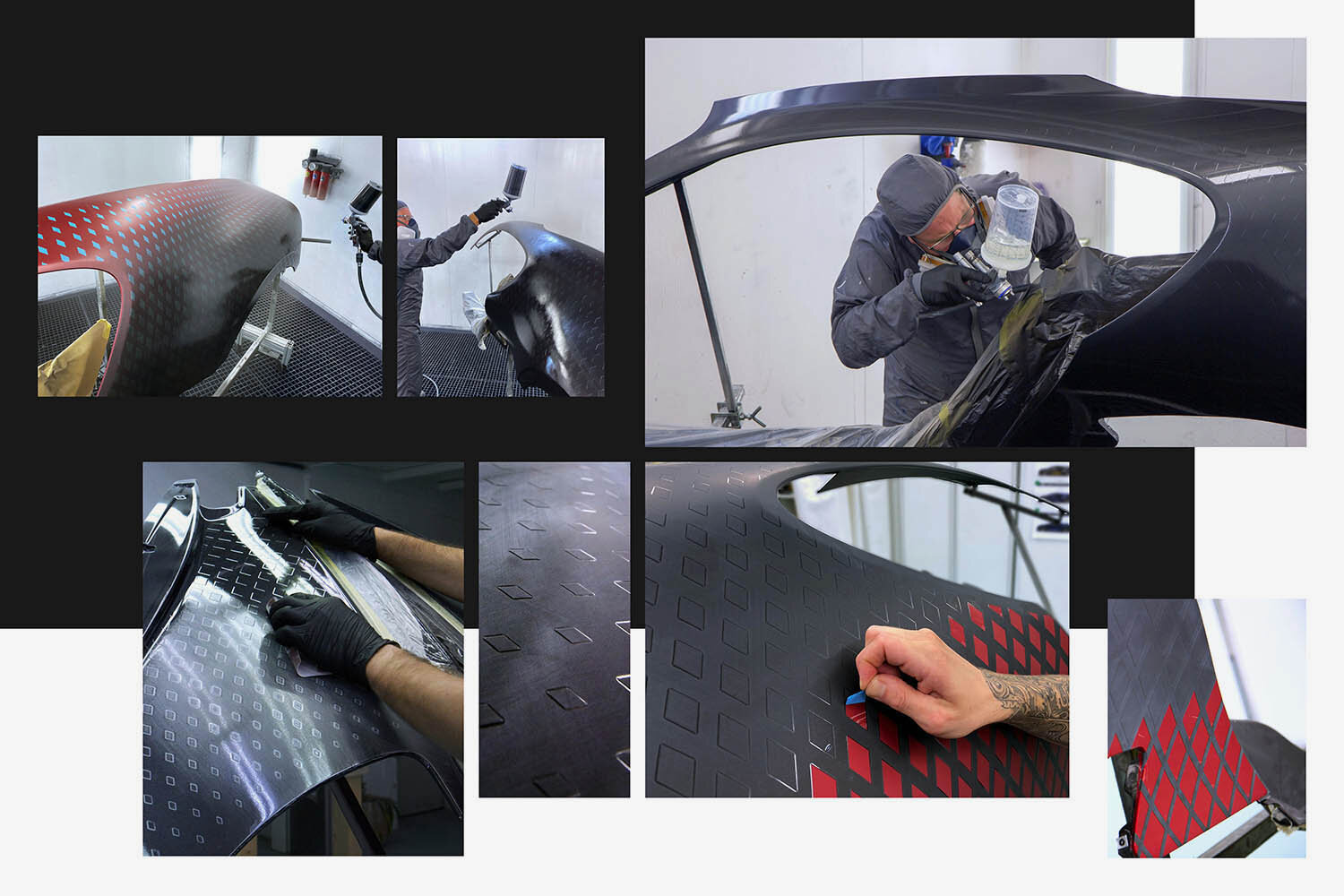

Once the Divo ‘Lady Bug’ had been finally processed, there were no major complications. Employees checked each and every diamond over several days to ensure that they were positioned accurately, trimming them if necessary or replacing the shapes. The next task was to perform the actual painting and the painstaking and meticulous removal of each diamond. ‘Graphite’ and clearcoat were applied on top of the effect paint ‘Customer Special Red’ in order to invert the pattern. As part of this process, the paintwork was sanded, smoothed, checked, retouched and then re-sanded. It took the paintwork artist over two weeks until his work was completed to perfection.

The multilayer paint structure now integrates the ruby diamonds evenly into an anthracite colour gradient. The process of repeatedly smoothing out the pattern created an extraordinary depth and brilliance in the colours. Months of hand craftsmanship were brought to completion.

Photos © Bugatti